Supply Chain

It is one third of a 20-foot (20-24") tube. This makes it possible to make three separate stock items. This allows you to purchase full tube lengths while not wasting material.

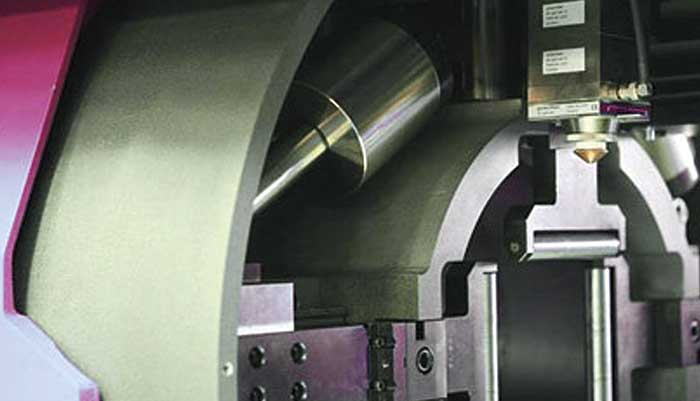

Parts can be held with automatic tabbering (in FabCreator), as well as a set of jaws at the drive chuck, and the idler-chuck.